Details

Industrial Subcategory:

Polishing, Finishing and Conditioning

Recommendations for use:

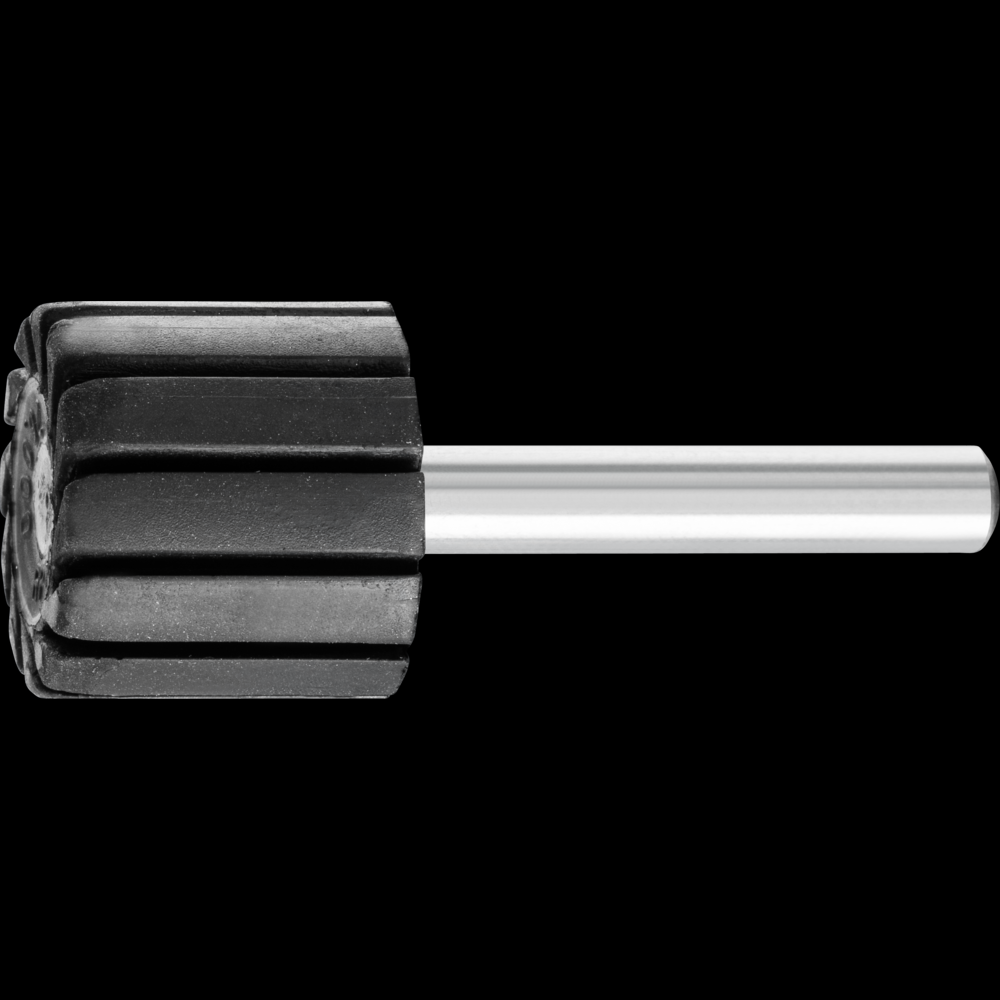

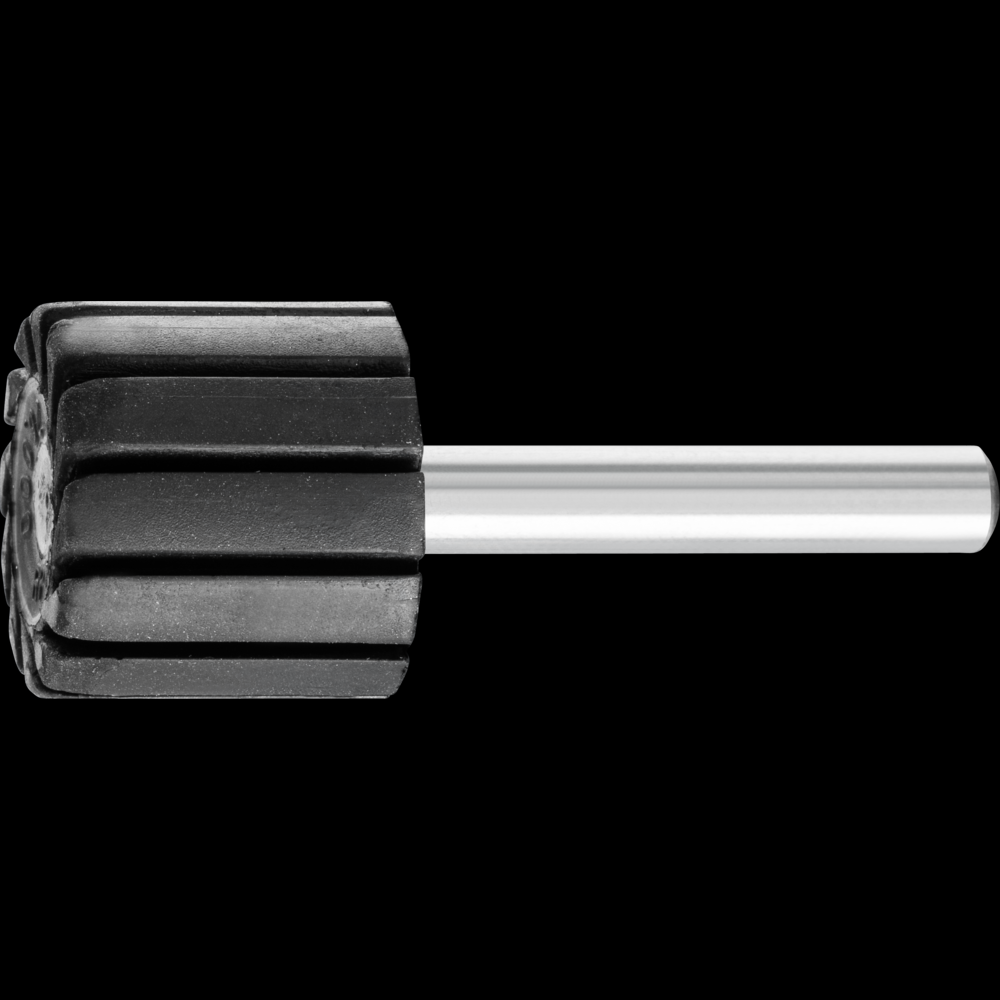

To easily change the abrasive spiral bands, give them a slight clockwise twist and pull them up and off. When doing so, leave the rubber drum holder clamped in the power tool.

Recommendations for use 1:

To ensure the abrasive spiral band is securely attached, follow the minimum speed for the rubber drum holder.

Recommendations for use 2:

For best performance, use at a recommended peripheral speed of 4,000-6,000 SFPM.

Safety notes:

The maximum permitted peripheral speed is 6,000 SFPM.

Manufactured By:

Pferd Inc.

Other Details

Abrasive spiral bands fit securely on the rubber drum holder as the holder expands during use.

Highest possible cost-effectiveness due to particularly high stock removal rate and aggressiveness of the abrasive.

Outstanding service life even under the toughest work conditions, due to special manufacturing.